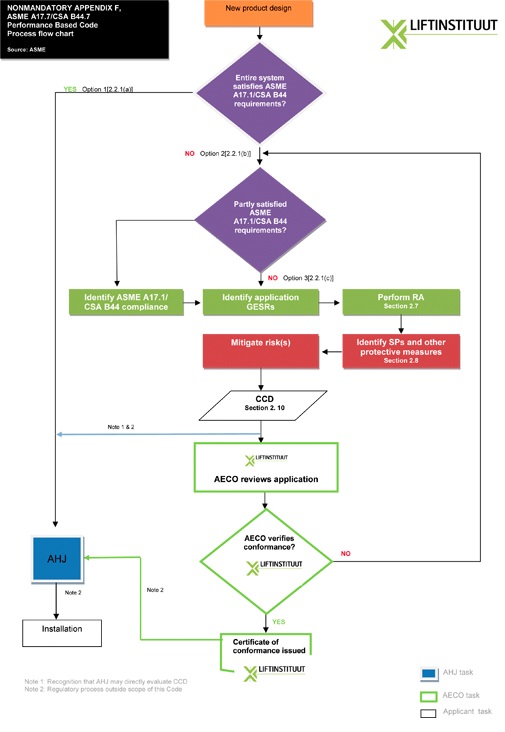

Product certification: based on prevailing standards in North America

In March 2009, Liftinstituut was officially appointed as an Accredited Elevator/Escalator Certification Organization (AECO) by the American National Standards Institute (ANSI) (ID#0842). As a result, Liftinstituut is qualified to certify elevators, escalators, and components for the North American market according to ASME A17.7/CSA B44.7.

In March 2009, Liftinstituut was officially appointed as an Accredited Elevator/Escalator Certification Organization (AECO) by the American National Standards Institute (ANSI) (ID#0842). As a result, Liftinstituut is qualified to certify elevators, escalators, and components for the North American market according to ASME A17.7/CSA B44.7.

Encouraging innovation

As in Europe, manufacturers can now deviate from ASME A17.1/CSA B44 as long as the product is completely safe, as evidenced by a risk analysis and assessment by an AECO. This development benefits manufacturers by encouraging innovation. For example, you can now use plastic buffers instead of steel springs and hydraulic buffers as described in A17.1. As a result, buffers can be much more compact. The elevator well can also be shallower. What’s more, plastic buffers don’t rust.

AECO technical website information based on ASME A17.7/CSA B44.7

All information about 'Application for Certification', 'Contents of Code Compliance Documentation' (CCD), 'Contents of Code Data Plate' (if certified), 'Evaluation', 'Contents of Liftinstituut Certificate of Conformance'. 'Fulfilling the requirements of the code A17.1/B44', 'Global Essential Safety Requirements' (GESRs). Risk Assessment Process, 'Protective measures and safety principles', 'Safety Parameters' (SPs) and other important issues related to product certification with Liftinstituut.

Download the flowchart as pdf-file.

Application for Certification

Before starting the product certification the applicant, as a minimum, shall provide Liftinstituut the following information:

The mandatory information required by A17.7/B44.7 for certification of elevator systems according to Appendix I, clauses I-4.2 and I-4.3:

- Name and address of the applicant or authorized representative and the place of manufacture of the elevator system;

- A written declaration that the same application has not been submitted to any other AECO, or a written explanation as to why the application is being submitted to another AECO;

- Details of the location where the elevator system can be examined. The elevator system submitted for examination and certification shall include all parts and be capable of serving at least three levels (top, middle and bottom) unless the system is specifically limited in scope to a two-stop application;

- Technical documentation (I-4.3):

§ Code Compliance Documentation (CCD);

§ A general description of the elevator system under examination, indicating all possible extensions to it;

§ Design and manufacturing drawings or diagrams;

§ Global Essential Safety Requirements (GESRs) taken into consideration and means adopted to satisfy them;

§ Results of any tests or calculations performed or subcontracted by the manufacturer, applicant, or installer;

§ Steps taken at the installation stage to ensure that the elevator system conforms to the requirements of A17.7/B44.7.

The mandatory information required by A17.7/B44.7 for certification of components, sub-systems and functions according to Appendix I, clauses I-3.2 and I-3.3:

- Name and address of applicant;

- Name and address of the manufacturer of the sub-system, component, or function or the authorized representative and the place of manufacture of the sub-system, component, or function;

- A written declaration that the same application has not been submitted to any other AECO, or a written explanation as to why the application is being submitted to another AECO;

- A representative sample(s) of the sub-system, component, or function or details of the place where it can be examined;

- Technical documentation (I-3.3):

§ Code Compliance Documentation (CCD);

§ A general description of the sub-system, component, or function, including its intended use (possible limitations such as speed, load, power, etc.) and conditions affecting use (such as explosive environments, exposure to the elements, etc.);

§ Design and manufacturing drawings or diagrams;

§ Global Essential Safety Requirements (GESRs) taken into consideration and means adopted to conform;

§ Results of all applicable tests or calculations performed or subcontracted by the manufacturer or applicant;

§ A copy of the assembly instructions for the sub-system, component, or function;

§ Steps taken at the manufacturing stage to ensure that the series-produced sub-system, component, or functions conforms to the sub-system, component, or function examined.

Contents of Code Compliance Documentation (CCD)

A CCD shall be produced for each design (system, sub-system, component, or function) for which safety has been assessed for conformance with the A17.7/B44.7 and shall include:

- An overall description of the equipment;

- A description of a particular elevator system, sub-system, component, or function to which the A17.7/B44.7 is being applied;

- A list of A17.1/B44 Parts, sections, or requirements that have been addressed by compliance with A17.7/B44.7;

- Technical documentation necessary to demonstrate conformity and enable verification of conformance;

- A list of applicable GESRs;

- The risk assessment report, including team members, their relevant expertise and experience, and date op completion of the risk assessment processes;

- Procedures for acceptance inspections and tests to verify conformance with the CCD;

- Procedures for tests, periodic inspections, maintenance, replacements, adjustments, and repairs to be incorporated into and made a part of the maintenance Control Program (MCP according 8.6.1.2.1 of A17.1/B44).

Contents of Code Data Plate (if certified)

For elevator system certification based on A17.7/B44.7 the " normal" Code Data Plate shall be provided according A17.1/B44 Section 8.9 including statement: "This elevator complies with ASME A17.7/CSA B44.7. See Maintenance Control Program."

The elevator sub-system or component shall be labelled, marked, or tagged with the following data:

- The name or trademark of the manufacturer, or Liftinstituut Certificate of Conformance identification by which the organization that manufactured the device can be identified;

- The Liftinstituut mark;

- The Liftinstituut Certificate of Conformance identification;

- Statement of compliance with ASME A17.7/CSA B44.7;

- A distinctive type, model, or style letter or number;

- Any conditions of validity of the certificate and any particulars necessary to identify the type of sub-system or component certified.

Evaluation

What is the role of Liftinstituut as an AECO during certification?

- Evaluate the products of the applicant against the requirements of A17.7/B44.7;

- Examine the technical documentation to verify that the elevator system, sub-system, component or functions meet the relevant GESRs;

- For elevator systems perform or have performed the appropriate checks and tests necessary to determine that the elevator system meets the requirements of A 17.7/B44.7;

- For sub-systems, component or function perform or have performed appropriate checks and tests necessary to determine whether the solutions adopted by the manufacturer of the sub-system, component or function meets the requirements of A17.7/B44.7, allowing it to carry out its function when correctly fitted on an elevator as specified in the manufacturer's CCD.

Contents of Liftinstituut Certificate of Conformance

If Liftinstituut issues a certificate the contents of this certificate will be at least:

- The name and address of the supplier whose products are the subject of certification;

- The scope of the certification including:

- The products certified (which may be identified by type or range of product);

- The relevant parts of A17.7/B44.7 to which each product or type is certified;

- The certification system 3 according to ISO/IEC 17065: 2013; - Effective date of the certificate and the term of the certification.

Fulfilling the requirements of the code A17.1/B44?

If your design fulfils the requirements of the code A17.1/B44 than a product certification according to A17.7/B44.7 is not needed. But sometimes it is maybe not that clear. Because the use of new technologies or a new approach will lead to different understanding or interpretations of the code. Based on this you can ask Liftinstituut for a pre-certification procedure to find out compliance or non-compliance with the A17.1/B44 code. We will issue a report with our findings related to the applicants contract.

Global Essential Safety Requirements (GESRs)

Deviating from the code A17.1/B44 means that your design shall assure safety on performance-based level instead of code level by using Global Essential Safety Requirements (GESRs). These GESRs are grouped on the basis of locations where a person could be exposed to a hazard, hazardous situation, or harmful event:

- At different locations;

- Adjacent to the elevator;

- At the elevator entrance;

- Inside the car;

- Working areas.

There are two approaches for identifying applicable GESRs. The first one is based on checking all the GESRs (in total 48) and find out or they are applicable for your product. It does not matter if it is an elevator system, sub-system, component, or function. If conformance with applicable GESRs is not self-evident, risk assessment shall be completed to demonstrate conformance. The second approach is based on risk scenarios that could occur during operation and use, maintenance, inspection, and testing of the product. Be aware of the fact that these risk scenarios considered throughout the life cycle of the product. During development and formulation of each risk scenario you have to consider and describe the hazardous situations, possible causes, and effects.

Finally safety of a product is achieved when:

- All risk scenarios related to the subject of assessment are identified and formulated;

- Risk assessment is conducted in accordance with ISO 14798 or other equally methodologies;

- Appropriate SPs are implemented;

- The conclusion of the process shall be that the requirements of applicable GESRs and SPs have been met or hazards identified in the scenarios have been eliminated or safety risks sufficiently mitigated.

Risk Assessment Process

The Risk Assessment Methodology in A17.7/B44.7 is based on ISO 14798 although other methodologies for analyzing hazards and estimating risks are equally acceptable. The main fundaments of a Risk Assessment Process are:

- A balanced and qualified Risk Assessment Team;

- Risk Scenario;

- Risk Estimation;

- Risk Evaluation;

- Risk Assessment records.

Protective measures and safety principles

If risk evaluation concludes that the level of risk requires mitigation, protective measures shall be implemented in the following order:

- Eliminate the hazard, where possible, by changing the design;

- If the hazard cannot be eliminated further measures shall be taken to reduce the risk;

- Eliminate or minimize the probability of defeat or circumvention of protective measures, such as guards, safety devices, etc.;

- If the hazard cannot be mitigated by above mentioned steps, inform users and authorized personnel of residual risks by one or more protective measures:

- Information;

- Training;

- Warning signs;

- Use of personnel protection equipment, etc.

Safety Parameters (SPs)

The Safety Parameters are a way of filling in and awareness of de GESRs. It can be useful during Risk Assessment, evaluating risks, and determine that a risk has been sufficiently mitigated.

Other important issues related to product certification with Liftinstituut

As an applicant try to involve Liftinstituut in the early stage of the project because that will help the estimated project schedule being successful. If you start to involve us at the end of the project you will maybe confronted with undesirable surprises and unexpected delays.

After successfully finishing the product certification Liftinstituut will issue a Certificate of Conformance with a term of three years. Within these three years we will perform a surveillance check required by ISO/IEC 17065: 2012 to see if the product still meets the requirements as certified.

If the applicant changes or modifies the design of the certified product and it has its influences in safety than the applicant has to inform the Liftinstituut. The Liftinstituut will examine the modifications and inform the applicant whether the Certificate of Conformance remains valid. Otherwise the Liftinstituut will revise the Certificate of Conformance and its belonging report if the product still meets the requirements of the A17.7/B44.7.

For support in setting up a Risk Assessment we can arrange a general course based on our, long term experience and knowledge in this elevator and escalator field. Of course the applicant has to set up his own Risk Assessment Team without Liftinstituut interference for preparing product certification CCD.